Ahmedabad - 382445, Gujarat, India

Ahmedabad - 382445, Gujarat, India  Ahmedabad - 382445, Gujarat, India

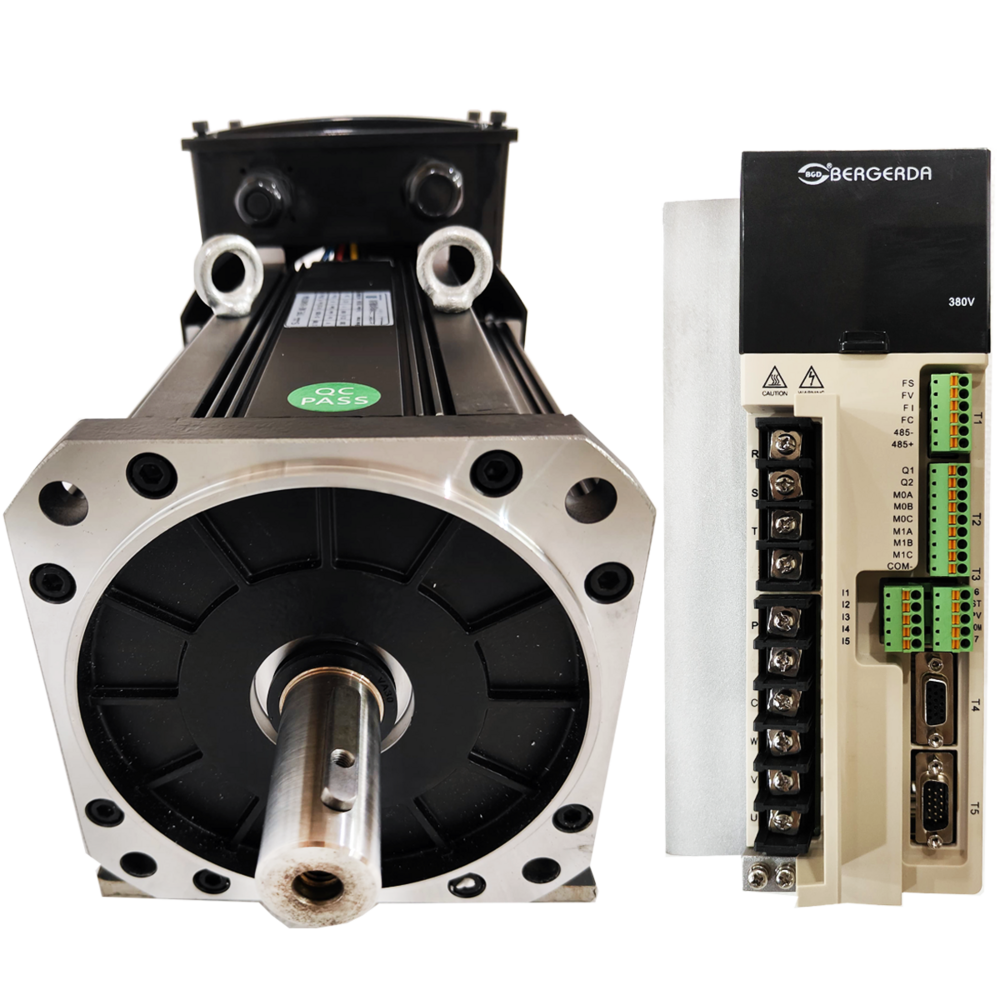

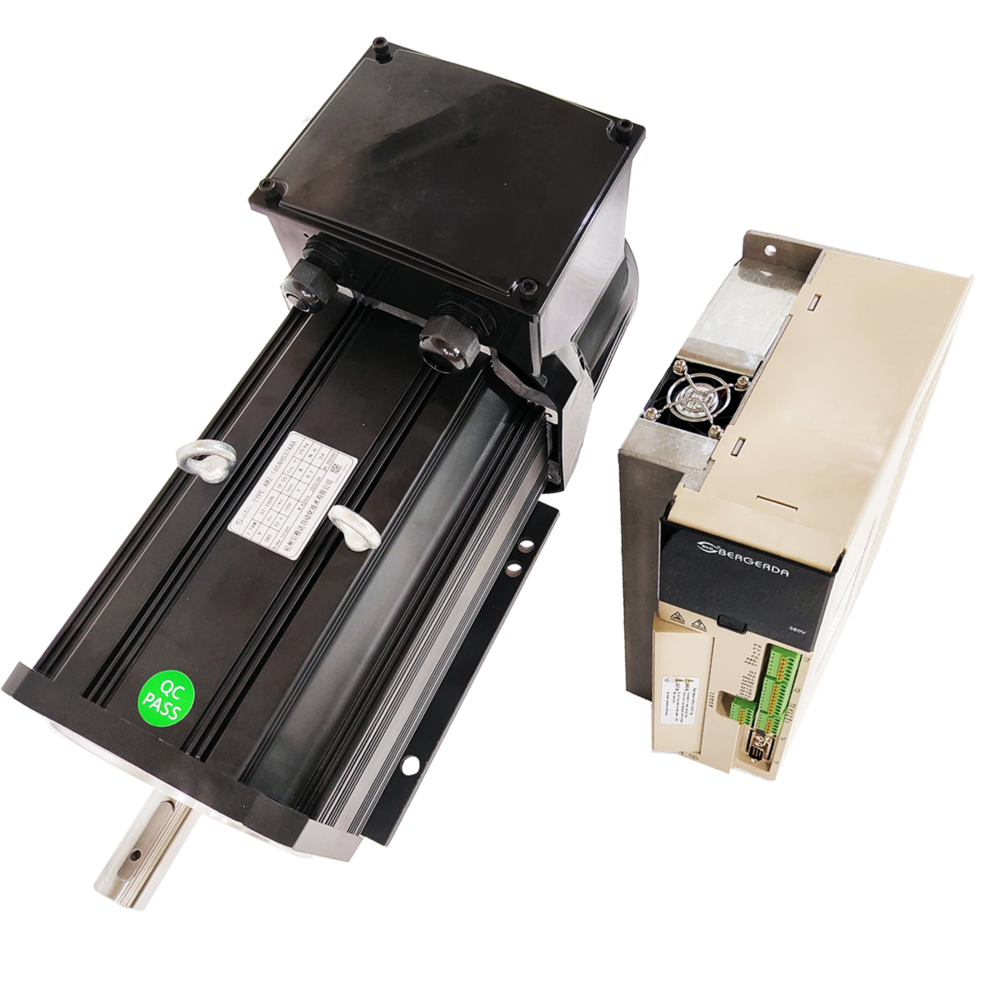

Ahmedabad - 382445, Gujarat, India Spindle Servo Motor and Drive

उत्पाद विवरण:

- उपयोग CNC Machine

- प्रॉडक्ट टाइप Spindle Servo Motor

- उपयोग करें CNC Machine Spindle

- वज़न किलोग्राम (kg)

- एप्लीकेशन Milling Drilling

- रंग Black

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Spindle Servo Motor

- Milling Drilling

- CNC Machine

- CNC Machine Spindle

- Black

- किलोग्राम (kg)

उत्पाद वर्णन

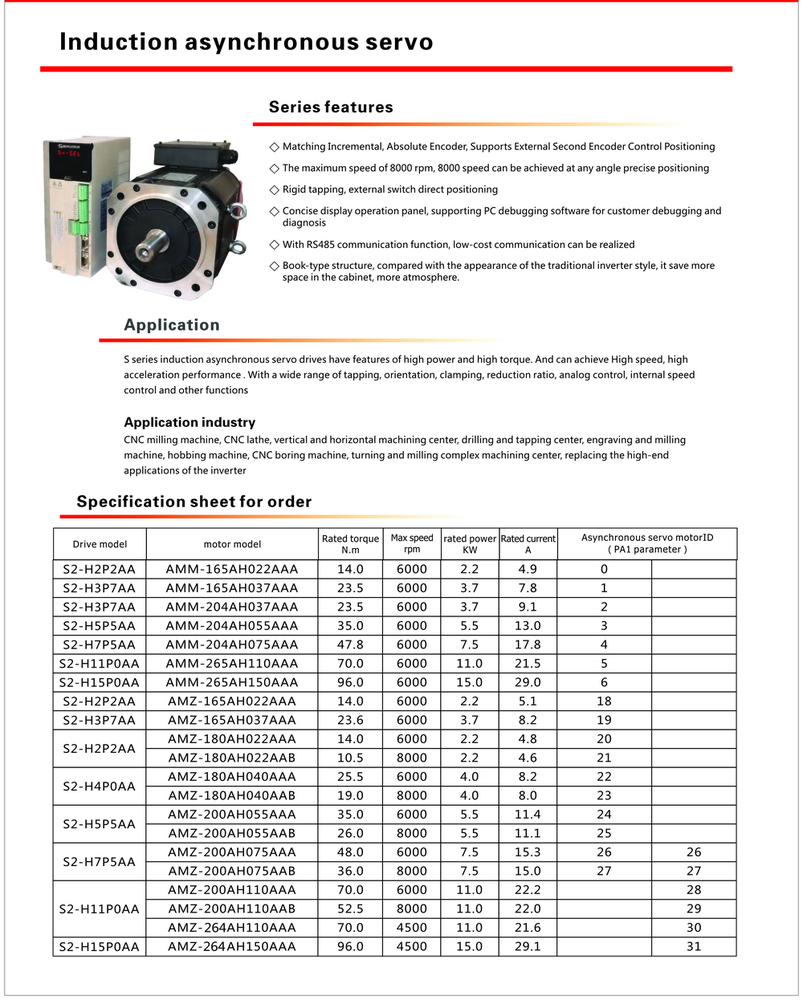

Technical Specification

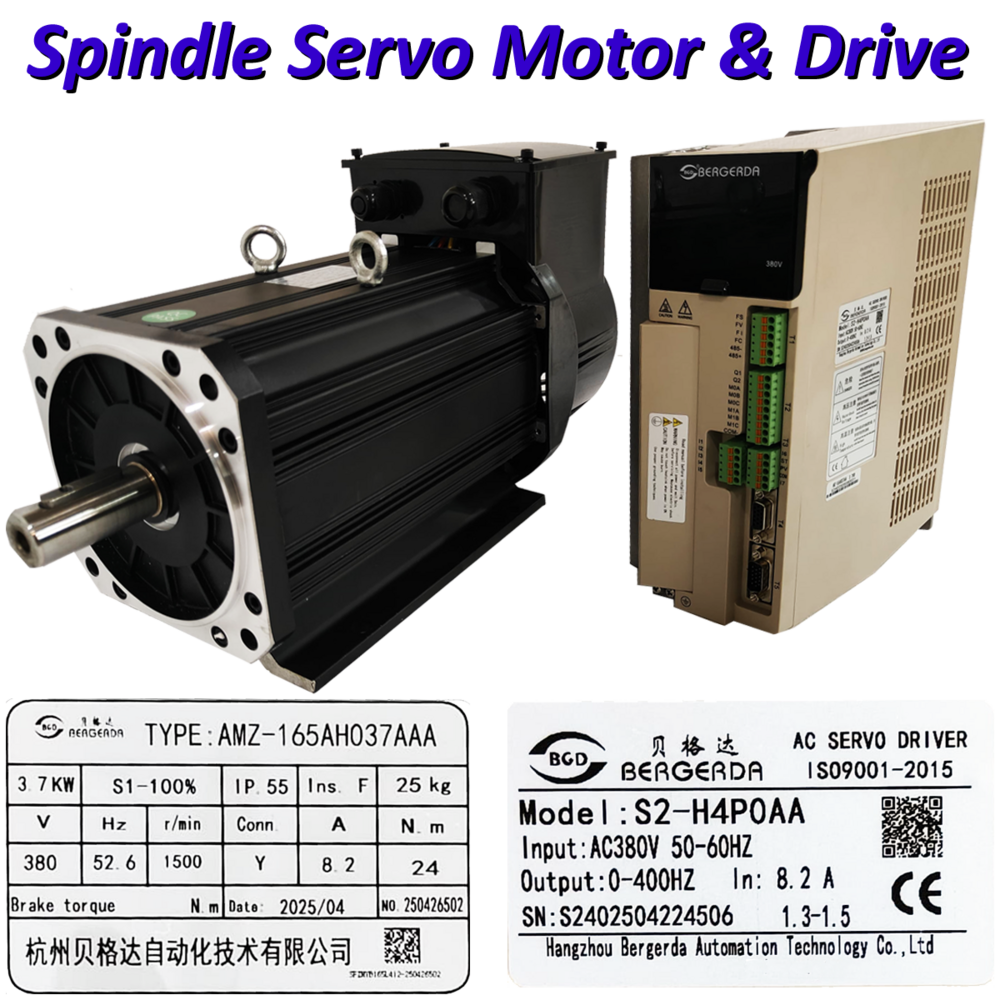

Product: Bergerda Spindle Servo Motor and Drive

Power Range: 0.75 kW to 15 kW

Rated Voltage: 380V (confirm as per model)

Rated Speed: 1500 to 6000 rpm (based on motor model)

Frequency: 200-400 Hz

Cooling Method: Shaft fan / External fan cooled

Encoder Type: Optional (Incremental / Absolute / Resolver)

Protection Class: IP54 / IP55 (confirm per model)

3.7 kW Spindle Motor AMZ-165AH037AAA

Servo DriveS2-H4P0AA

Key Features

High-speed operation with low noise and stable torque

Compact and lightweight design for easy machine integration

Precision balanced rotor for minimal vibration

Reliable insulation and bearing design ensuring long life

Compatible with Bergerda spindle drives and controllers

Available with air-cooled (based on series)

Wide application in CNC machining centers, engraving machines, wood routers, and metal cutting systems

Global service support with offices in India, Brazil, Ecuador, Mexico, Spain, and Poland

Enhanced Precision for CNC Operations

Engineered for stability and accuracy, our spindle servo motor and drive dramatically improves the precision of milling and drilling processes. Delivering consistent torque and speed, it optimizes your CNC machines capabilities for demanding tasks, ensuring fine finishes and reliable results throughout operation.

Reliable Performance Designed for Durability

This black-finished unit weighs 20 kilograms, contributing to its stable operation in various CNC machine setups. Built to endure demanding manufacturing environments, it promises low maintenance and a long operational lifespan, reducing the total cost of ownership.

FAQs of Spindle Servo Motor and Drive:

Q: How is the spindle servo motor and drive used in CNC machines?

A: The spindle servo motor and drive are installed as the main spindle unit in CNC machines, providing the rotational force needed for high-precision milling and drilling operations. It ensures smooth, accurate control of speed and torque during machining.Q: What are the main benefits of using this spindle servo system?

A: The primary benefits include improved precision, efficient energy consumption, reduced maintenance needs, and enhanced machining consistency. It also contributes to increased productivity by delivering stable spindle performance.Q: When should I consider upgrading to this spindle servo motor and drive?

A: You should consider upgrading if your current spindle system lacks accuracy, efficiency, or reliability, or if production requirements have increased and demand more robust performance for continuous CNC operations.Q: Where can this spindle servo motor and drive be applied?

A: This product is ideal for use in CNC milling and drilling machines across various industries, including manufacturing, automotive, aerospace, and mold making.Q: What is the typical process for installation?

A: Installation involves mounting the servo motor as the spindle onto the CNC machine, connecting the drive unit, and calibrating the control parameters to match your machines requirements before starting operations.Q: How does this product benefit exporters, manufacturers, and suppliers?

A: With high-quality components and consistent performance, exporters, manufacturers, and suppliers benefit from reduced warranty claims, satisfied end users, and smoother integration into CNC machinery.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें